Zero perfluorinated hydrocarbon* emissions

when plasma etching wafers and PCBs

* also known as HFCs, F-gases, PFCs*

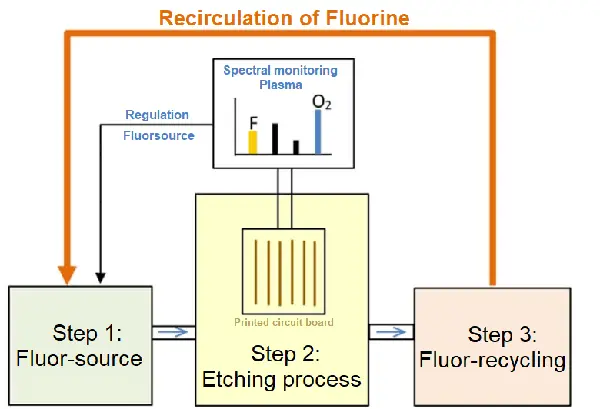

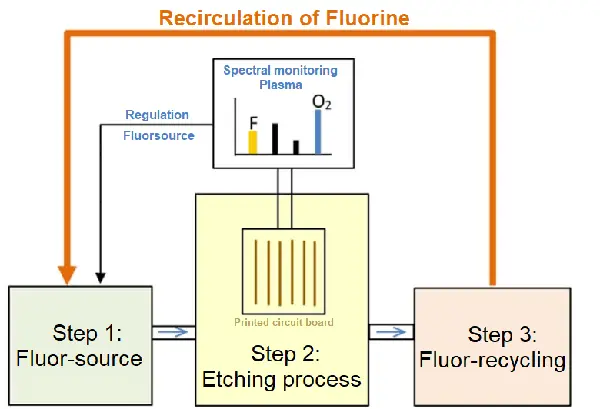

Schematic representation of the process stages

when plasma etching wafers and PCBs

* also known as HFCs, F-gases, PFCs*

The research project between plasma technology GmbH and Furtwangen University (HFU) encompasses an investigation into a new low pressure plasma process and system concept, including its implementation for printed circuit board applications. This is to be achieved by means of a directly interconnected multi-stage, hermetically sealed recirculating low pressure plasma process.

The dry or plasma etching process is used increasingly in these industries resulting in considerable amounts of fluorinated greenhouse gases being released.

The substances typically used as etching gases,

These gases have 7,390 (CF4) to 12,200 (C2F6) times the greenhouse effect of CO2.

Plasma etching plays a decisive role in printed circuit board manufacturing due to

the increasingly complex circuit structures and growing demands on the quality of the contacting and interconnection surfaces.

For example, the process is used for etching back circuit layers in multilayer PCB assemblies, surface activation and structuring, or cleaning holes for through-hole plating.

In semiconductor manufacturing it is used for substrate structuring and also for cleaning CVD coating equipment.

Alternative, HFC-free process gases that are characterized by inadequate etch rates, process stability and processing results.

Cleaning systems that ensure effective and energy-efficient separation of the very stable fluorine compounds from the process exhaust air, are not yet available.

Therefore, there is a great danger that the necessary HFC emission reductions for the printed circuit board and semiconductor industry will soon become a very real problem - not only in Europe, but worldwide.

Global emissions of perfluorinated hydrocarbons (also known as HFCs, F-gases, PFCs) are a significant component of climate change due to their extremely high global warming potentials and longevity in the atmosphere.

Their use was pushed about 30 years ago as an alternative to ozone-depleting CFC compounds in air conditioning and refrigeration systems, sprays, foams and insulation material and fire extinguishing agents. These have been rightly clearly regulated since the 2016 Kigali Climate Conference, where 150 countries agreed to drastically reduce consumption.

For industrialized countries, a gradual reduction by a total of 85 percent by 2036 was agreed, while developing and emerging countries committed to reduction targets of 80 and 85 percent by 2047.

At first glance, these targets are primarily linked to the rapidly growing demand for air-conditioning equipment, for which, however, natural substitutes such as ammonia, CO2 or propane are already available.

However, the specifications apply equally to industrial production processes.